Metalworking has seen significant advancements in recent years, with innovative techniques transforming projects’ approach. Among these, a particular method has gained prominence for its ability to deliver precision and efficiency. This approach has set a new standard in the industry, raising the bar for what can be achieved in metal fabrication.

Laser cutting in Perth has become a game-changer in Perth, revolutionising the local metalworking industry. This advanced technique has redefined the standards of craftsmanship, offering unparalleled accuracy and versatility. By embracing this technology, Perth-based fabricators are leading the charge in setting new industry standards, making the city a hub for high-quality metalwork.

Precision Beyond Compare

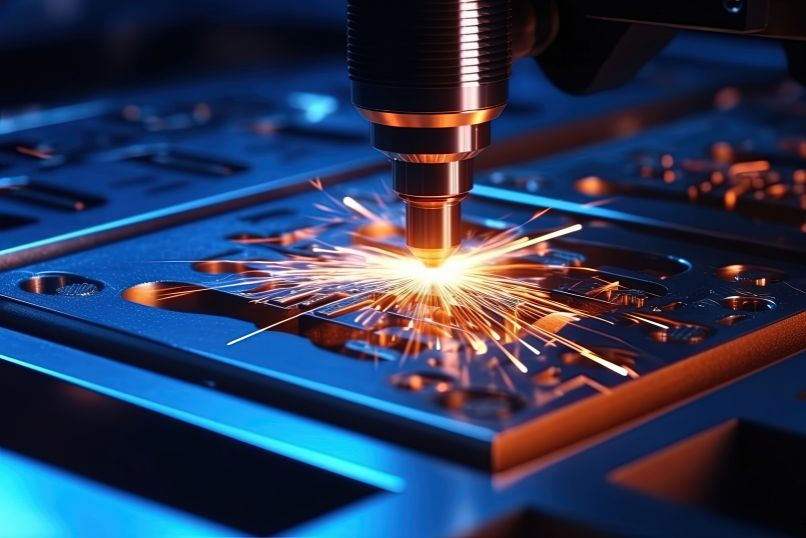

In metalworking, accuracy is paramount. The introduction of laser cutting has significantly enhanced the ability to achieve unparalleled precision in creating intricate designs. This method utilises focused beams of energy to meticulously slice through various materials, resulting in clean, sharp edges without additional finishing.

The precision offered by this technology surpasses traditional methods, ensuring that even the most complex designs are executed with exacting detail. The result is a level of craftsmanship that sets a new standard in the industry.

Efficiency That Saves Time and Resources

Efficiency is crucial in any manufacturing process, and the modern approach to metalwork has dramatically improved it. By adopting laser-based technology, Perth-based workshops can now execute projects much faster. This process allows for the cutting of multiple sheets simultaneously, significantly reducing the time needed for production.

Moreover, the minimal waste generated by this technique ensures that resources are utilised optimally. Reducing material wastage leads to cost savings and contributes to a more sustainable approach to fabrication.

Unmatched Versatility in Applications

One of the standout features of this cutting-edge technique is its versatility. Whether working with stainless steel, aluminium, or other metals, this method can handle various thicknesses and types of materials. This adaptability makes it suitable for various applications, from intricate decorative pieces to robust structural components.

In Perth, this versatility has opened up new possibilities in industries such as construction, automotive, and even art installations. Seamlessly transitioning between different projects makes this process invaluable in the diverse market.

Safety and Automation in the Workplace

Safety is an important consideration in any industrial setting, and the adoption of laser technology has introduced significant improvements in this area. The automated nature of this method means that human interaction with dangerous machinery is minimised. Operators can control the entire process safely, reducing the risk of accidents.

Additionally, the precision of the technology ensures that the material is handled with care, further enhancing safety by reducing the chance of mishaps. The focus on safety protects workers and boosts overall productivity by minimising downtime due to accidents.

The Future of Metalwork in Perth

The influence of advanced cutting technology in Perth is not limited to current projects; it is also shaping the future of the metalworking industry. As more businesses adopt this approach, the standards for quality and efficiency are continuously rising. This trend pushes the boundaries of what is possible in metalwork and encourages innovation and creativity.

With ongoing technological advancements, the potential for further precision, speed, and versatility enhancements is immense. Perth is poised to remain at the forefront of this evolution, leading the way in setting new benchmarks for excellence in metal fabrication.

Laser cutting in Perth revolutionises metal fabrication standards, offering unmatched precision, efficiency, and versatility. This advanced technology enhances the quality of metalworking and sets new benchmarks for safety and resource management. As the industry continues to evolve, Perth is critical in shaping the future of metal fabrication.