Many facility managers get this lesson the hard way. Your filters run low. You order them. You wait. You order from someone who tells you they can ship in a timely manner. You wait and wait.

Then your third follow-up call comes in and you’re told they have a backorder they’re just now letting you know about. It’s day ten. Your HVAC system is running on strain because it hasn’t been effectively filtered. You’re going to pay premium pricing to someone else who guarantees immediate delivery.

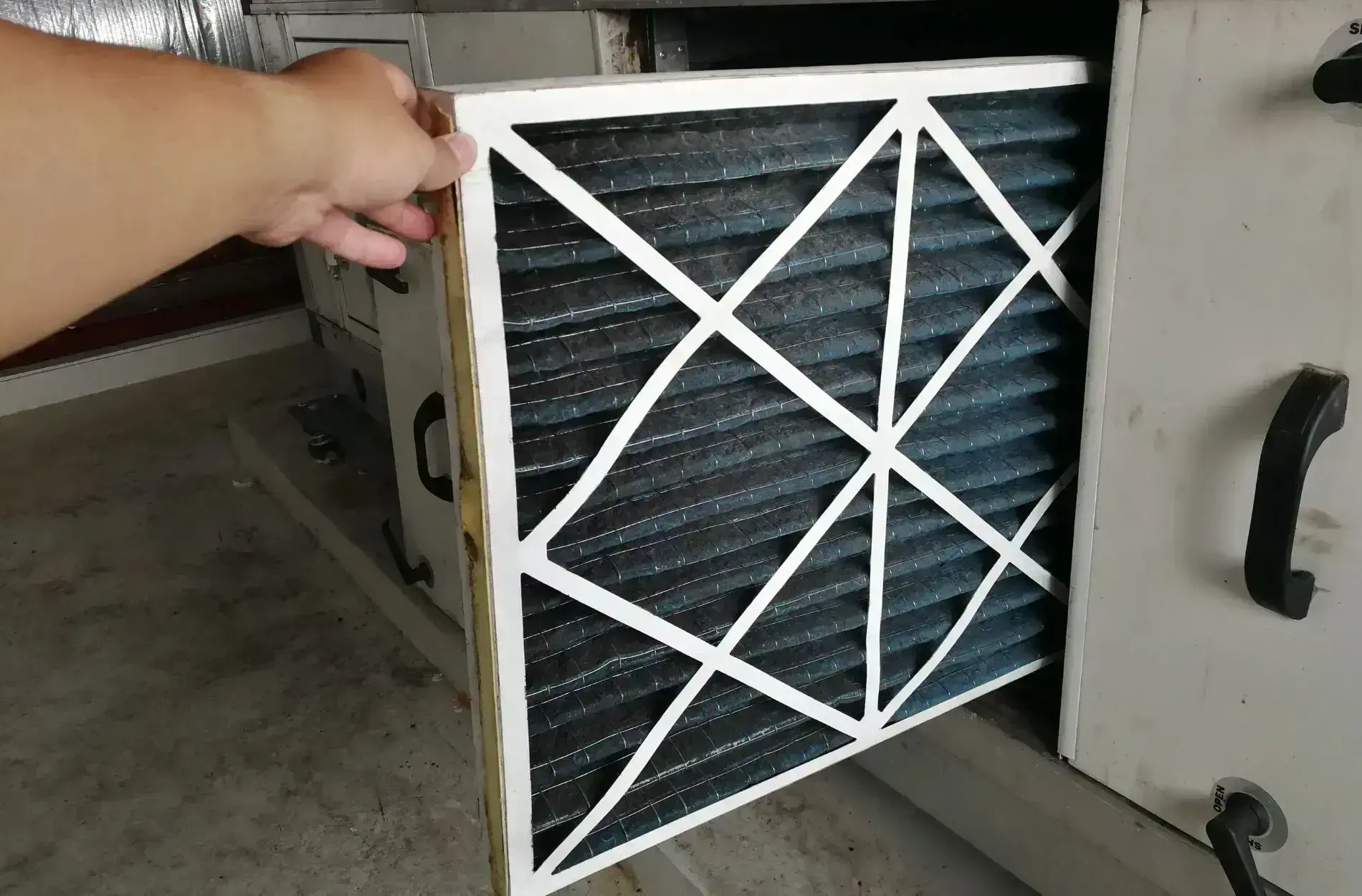

You’re losing money every day your filters aren’t doing their job. Yes, the replacement filters cost a couple hundred bucks for a reason but with every day that dirty filters are utilized, or filters that haven’t been changed in a couple weeks, additional costs accumulate that no one sees right away.

During Delays, Energy Expenditures Increase

For example, your system uses more energy to try to function with strained operations. Equipment accumulates wear and tear faster than it would otherwise. If you’re a commercial facility in need of cleanliness (e.g. health care, food service) you’re likely looking into compliance violations sooner than later which puts any filter bill on the back burner.

This is what happens: your filters are supposed to be replaced. You ordered them. They’re on borrowed time. You’ve got a week of decent air flow/exchange ahead of you before it starts getting noticeable enough that people complain.

You order from someone who three months ago said they could order them cheap and get them to you in five business days max. By day six you check in and you’re told, “We’re checking on it.” On the eighth day, you hear about a backorder that was never mentioned on days one or two and now you’re scrambling so your HVAC system doesn’t have to operate for another four days through an already hard situation.

This happens thousands of times a week across buildings everywhere by the month and the problem is when facilities choose to filter shop, it sounds good until they realize how much actual delay costs them in the end.

Where Local Availability Makes a Difference

It’s one thing to have local access with an air filter company near me that has supply on hand versus a distributor that drop ships through a warehouse several states away without you ever seeing first-hand what exists in real life for immediate pick up if necessary.

Filter shortages are never easy but when you need filters, you need them NOW – not next week, not whenever the shipment gets there – but companies that understand commercial operations keep sizes on hand that are frequently needed for emergencies because they understand emergencies happen. They aren’t just looking to capitalize on inventory costs and leave you holding the bag.

In addition, there are local concerns that facilitate need for certain sizes over others. If you’ve got high pollen count during the spring months or industrial pollution across town, a local supplier understands this. They’ve seen it happen through other buildings with similar issues and can actually provide useful feedback instead of droning off of a spec sheet.

What Good Companies Have in Common

The good filter suppliers have commonalities, but those commonalities do not include who can give you the least amount per filter. They include:

They answer their phones – call these people at 4:30 PM on a Friday and see if anyone picks up; if they don’t pick up when you need them from a legitimate emergency situation, they’re not actually commercial filter suppliers but vendors.

They know their inventory – they have filters on hand; when you call about a size, they know if they have it; they’re not checking and calling you back because they have an outdated inventory system.

They also recognize urgency – they know that if restaurant kitchen exhausts fail, it’s not just an issue for the chef but a compliance violation; if maintenance calls them about a data center cutting off filtration, they’re talking about millions of dollars worth of equipment potentially failing.

What Questions Don’t Matter

Forget their “good intentions” or all of the market lingo about “quality control.”

Ask them what’s their average delivery time for common sizes – not delivery times in general but their average for the last season/month/year – if they can’t give you a straight answer or hedge, take note.

Ask them what happens if they don’t have stock when you initially order – do they have friends elsewhere or do you wait?

Finally, can you pick up orders – that’s right; sometimes it’s easier if someone goes to retrieve something needed than just waiting an entire weekend – or week – for something you could grab sooner rather than later.

Question brand tolerance; can they work with your specifications? Maybe your industry needs particular brands for compliance reasons – does that matter or do they only have one or two brands available that work?

Where the Extra Costs Come From

It’s clear that most facility managers recognize the cost of the actual filter – in sum – but what no one factors in is how much real money disappears from places where filter costs don’t exist.

For starters – emergency orders cost more; if you’re desperate enough, you’re going to pay whatever it takes even if an out-of-state vendor charges you 40-50% more than a local supplier.

Equipment damage occurs – the last thing anyone wants is their mechanical systems going down; running them past efficient life only hinders replacement value – bill contractors for larger expenses because facility managers don’t actively factor damage caused by operational systems outside of their lifespan unless it benefits budgetary concerns.

What Does Your Supplier Expect of You?

It’s important to build relationships with good filter suppliers once you find one that actually shows up.

First – and this might sound unrealistic – provide lead time when appropriate so they can help out as best as possible. Communication is key. If your facility sees an uptick or down tick in expected useage with filters, let them know so they can adjust stocking accordingly.

Provide timely payment for invoices; reliable filter suppliers will take reliable payments seriously – if you’re late every 60 days at a time, don’t be surprised when your orders take second priority.

If you constantly find yourself filtering prices out with others to save a couple bucks on each filter you’re wasting your breath – you’ll get hit harder for expedited service first.

Why It’s Always Better to Be One Step Ahead

You should be one step ahead of supply needs. While it’s not appropriate to stock six months worth of filters, holding one cycle worth makes sense; if you change your filters every quarter then having another pack already acquired does not create crisis situations for supply shortages.

Establish deliveries with your supplier so they come when needed and many times, they provide better pricing for scheduled deliveries because it helps their inventory as well.

Track useage patterns for all seasons; generally speaking, most facilities use more filters during certain seasons – they’re either higher in useage during certain times depending on occupancy rates – or they wish they’d stock up but others beat them to the punch.

You don’t need to operate under crisis mode – it’s fine to prepare ahead of time with consistent suppliers but never without one that shows up!

Bottom Line? It’s Not Cheap Filter Costs That Matter

It’s not about finding good cheap commercial filter costs – it’s about ensuring reliable suppliers understand that when you need something they’ll be there – to hopefully save you money elsewhere!

Everything else is just details!

- Beyond the Annual Donation: Advanced Giving Strategies That Work

- What Changes When You Switch From Reactive to Proactive Security

- What Actually Goes Into Running a Successful Corporate Conference

- How the Best Companies Build World-Class Executive Teams

- What Happens During a Professional Water Safety Assessment